The breakthrough in heat dissipation technology for power devices

In the core systems of new energy vehicles, data centers and 5G base stations, power devices are facing unprecedented heat dissipation challenges. When the power density of IGBT modules exceeds 15kW/cm², traditional heat dissipation solutions are no longer able to meet the demands. A technological innovation centered on heat dissipation efficiency is reshaping the application boundaries of power devices.

The performance breakthrough of new heat dissipation materials

The innovation of phase change materials (PCM) brings new ideas for heat dissipation. The new type of composite PCM combines paraffin with graphene nanosheets, increasing its thermal conductivity to 5.2W/(m · K) and latent heat to 220kJ/kg. In the power module of electric vehicle charging piles, this material can control the junction temperature fluctuation within 15℃, significantly extending the device's lifespan. The more breakthrough is the liquid metal heat dissipation technology. The application of gallium indium tin alloy reduces the thermal resistance of the heat sink to 0.15℃/W, which is 80% lower than that of traditional silicone grease, effectively solving the problem of coordinated heat dissipation between the server CPU and power devices.

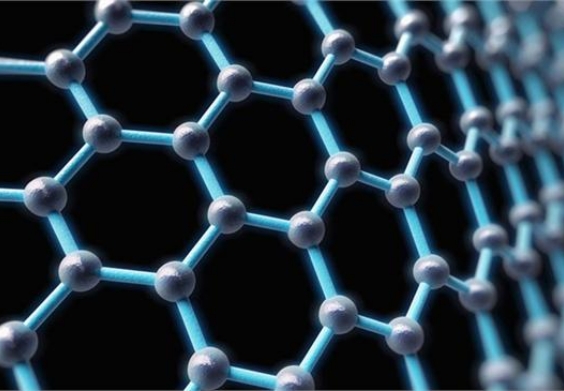

Important progress has also been made in the field of two-dimensional materials. The heat dissipation film made of hexagonal boron nitride (h-BN) nanosheets has an in-plane thermal conductivity of up to 800W/(m · K) when the thickness is only 50μm. When it is attached to the surface of the power MOSFET, the operating temperature of the device can be reduced by 12℃, and it also has excellent electrical insulation performance, providing new possibilities for the design of high-density power modules.

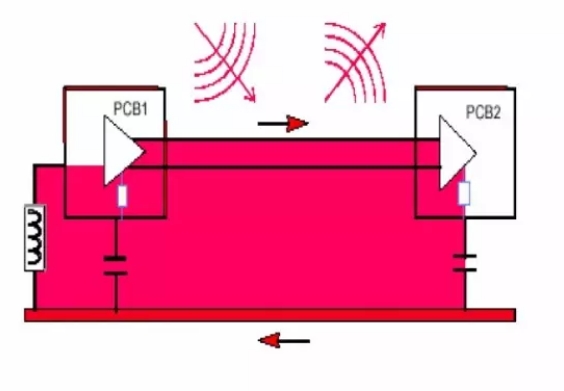

Structural innovation and multi-dimensional heat dissipation

Microchannel heat dissipation structures have been widely applied in power devices. The micron-level flow channels fabricated through the photolithography process increase the contact area between the coolant and the device by more than ten times. After a certain photovoltaic inverter adopted this technology, the volume of the heat sink was reduced by 40% and the heat dissipation efficiency was increased by 35%. The 3D stereoscopic heat dissipation architecture shortens the heat flow path by 60% by vertically stacking heat dissipation fins and vapor chambers. In high-density power modules, it can achieve a heat dissipation capacity of 30W per square centimeter.

Thermal radiation enhancement technology has become a new research direction. The heat sink coated with a nano-scale photonic crystal structure on its surface has an infrared emissivity increased to 0.92. In a natural convection environment, its heat dissipation capacity is 25% higher than that of ordinary heat sinks. This technology is particularly suitable for the heat dissipation of power devices in the aerospace field, achieving efficient heat dissipation without relying on complex liquid cooling systems.

The development of intelligent heat dissipation systems

The active intelligent cooling system is changing the traditional cooling mode. The composite heat dissipation module based on thermoelectric cooling (TEC) and micro-electromechanical systems (MEMS) can dynamically adjust the cooling power according to the real-time temperature of the power device. In the GPU cooling of gaming laptops, this system keeps the temperature fluctuation range of the devices within 5℃, while reducing the fan speed by 30%, effectively reducing noise. The introduction of artificial intelligence algorithms has further optimized the heat dissipation strategy. By predicting the load changes of power devices and adjusting the working state of the heat dissipation system in advance, the overall energy consumption has been reduced by 18%.

From material innovation to structural innovation, and then to intelligent control, every breakthrough in the heat dissipation technology of power devices is driving electronic systems towards higher performance and smaller size. In the era of high heat flux density, heat dissipation technology is no longer merely an auxiliary function but has become a core element determining the performance and reliability of power devices. Its progress will continue to empower the development of multiple strategic fields such as new energy and communication.