How does reconfigurable technology break functional boundaries

The flexible evolution of hardware architecture

Although traditional ASics (Application-Specific Integrated Circuits) can achieve efficient processing of specific tasks, their "one-time molding" feature leads to a design cycle of up to 18 to 24 months, and they are difficult to cope with the requirements of rapidly iterating algorithms. In sharp contrast, reconfigurable chips based on FPGA (Field Programmable Gate Array) can complete functional reconfiguration within a few hours. The latest heterogeneous reconfigurable chip has increased the computing power utilization rate of a single chip in data center servers from 45% to 78% by integrating GPU, AI accelerators and dedicated IP modules. This architectural flexibility is particularly crucial in the field of autonomous driving. A certain in-vehicle computing platform has reduced the system response speed by 200 milliseconds by real-time switching of lane recognition and obstacle detection algorithms.

Collaborative breakthroughs in materials and processes

The introduction of two-dimensional materials (such as molybdenum disulfide and black phosphorus) brings new possibilities to reconfigurable chips. The carrier mobility of this type of material is 5 to 10 times that of silicon-based materials, and it has the physical property of atomic-level thickness, which can be used to manufacture flexible reconfigurable transistors. By integrating a memristor array on a flexible substrate, researchers have successfully developed a neuromorphic reconfigurable chip capable of simulating the function of biological synapses, with energy consumption being only 1/50 of that of traditional AI chips. In addition, the low-temperature co-fired ceramic (LTCC) three-dimensional integration technology increases the wiring density of the chip by three times, enabling reconfigurable chips to maintain high performance while reducing their volume to one-third of the traditional solution.

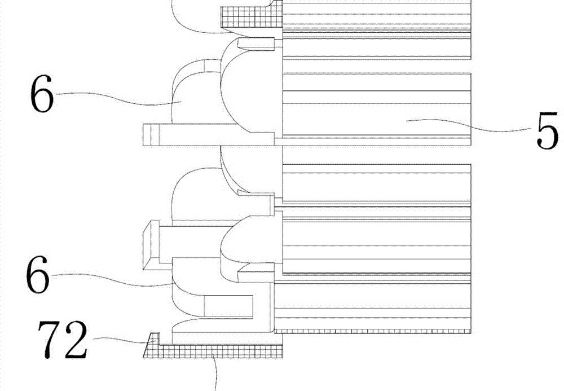

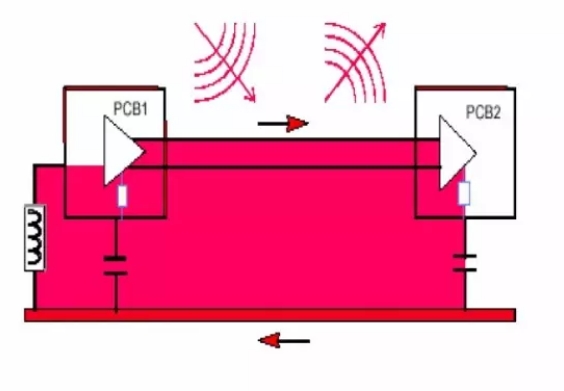

The paradigm shift of application scenarios

On the 5G base station side, the reconfigurable smart Surface (RIS) technology achieves the dynamic optimization of the signal reflection path by integrating programmable metamaterial units. A single RIS panel can replace 3 to 5 traditional base station antennas, increasing the network coverage efficiency by 40%. In the field of industrial Internet of Things, after edge computing nodes adopt reconfigurable chips, they can automatically switch between functions such as equipment monitoring, predictive maintenance and quality inspection according to real-time task requirements, reducing the amount of cloud data transmission by 70%. It is worth noting that in the aerospace field, reconfigurable chips have successfully solved the problem of functional failure caused by radiation in traditional aerospace chips through in-orbit reconfiguration, extending the service life of the equipment by 1.5 times.

This "metamorphosis" in the chip field is essentially the product of the deep integration of materials science, integrated circuit design and software-defined technology. As reconfigurable technology moves from the laboratory to large-scale commercial use, future electronic systems will no longer be confined to fixed-function hardware modules but will evolve into "intelligent agents" with adaptive capabilities. This transformation may completely rewrite all application scenarios from consumer electronics to industrial control.