How do resistors reshape the foundation of modern circuits

In the precision circuits of smart devices, communication base stations and new energy systems, resistors, which seem insignificant, are undergoing a quiet technological revolution. The performance breakthrough of this basic component used to limit current and regulate voltage is becoming a key force driving the upgrade of the entire electronic system.

Material innovation breaks through the performance ceiling

The accuracy of traditional metal film resistors has long remained at the ±1% level. However, with the maturity of nano-scale film deposition technology, new resistors have raised this index to ±0.01%. The temperature coefficient (TCR) of ruthenium oxide (RuO₂) film resistors fabricated by atomic layer deposition (ALD) process can be controlled within ±5ppm/°C within the resistance value range of 100Ω to 1MΩ, which is one order of magnitude lower than that of carbon film resistors. This improvement in accuracy directly empowers high-precision measuring instruments, reducing the voltage measurement error of multimeters to the microvolt level.

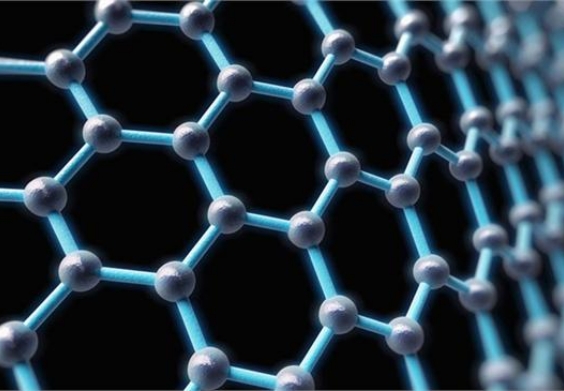

In the field of flexible electronics, breakthroughs have been made in stretchable resistive materials based on the composite of graphene nanosheets and silver nanowires. When the tensile strain reaches 30%, the rate of resistance change is only 0.3%, opening up a new path for the circuit design of wearable devices. Medical patch devices have thus been able to integrate more complex signal acquisition modules, significantly improving the accuracy of real-time monitoring data.

The challenge of miniaturization has given rise to 3D structural design

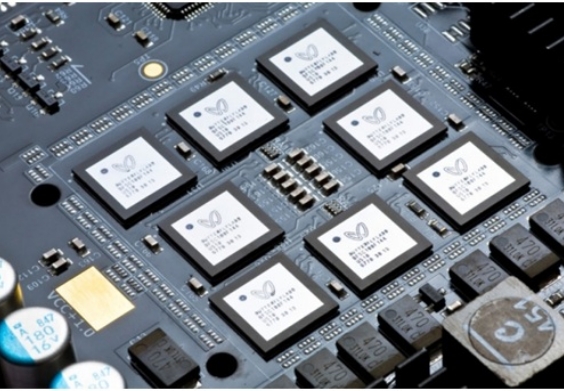

The dense RF circuits in 5G base stations impose strict requirements on resistors, and the traditional 0402 package can no longer meet the space demands. Through 3D stacking technology, the new type of resistor has achieved a wide resistance value range from 200mΩ to 10kΩ in the 01005 package size. This three-dimensional structure design not only reduces the occupied area by 60%, but also enhances the power carrying capacity to 125mW by optimizing the heat dissipation path, effectively solving the self-heating problem in high-frequency circuits.

The pursuit of low power consumption by sensor nodes in the Internet of Things has driven resistors to develop towards ultra-small size and ultra-low leakage. The RF resistor fabricated based on the principle of thin-film bulk acoustic wave resonator (FBAR) achieves 50Ω impedance matching within a 1.6×0.8mm² package, with a standby current as low as 10nA, which greatly extends the battery life.

The expansion of application scenarios triggers technological iteration

The battery management system (BMS) of new energy vehicles poses a dual challenge to shunt resistors: they must withstand a continuous current of over 200A while maintaining high precision within the temperature range of -40 °C to 125°C. The new type of metal alloy shunt resistor, through a special welding process and precise etching technology, controls the temperature drift within ±15ppm/°C, meeting the demand for precise monitoring of battery charging and discharging states in electric vehicles.

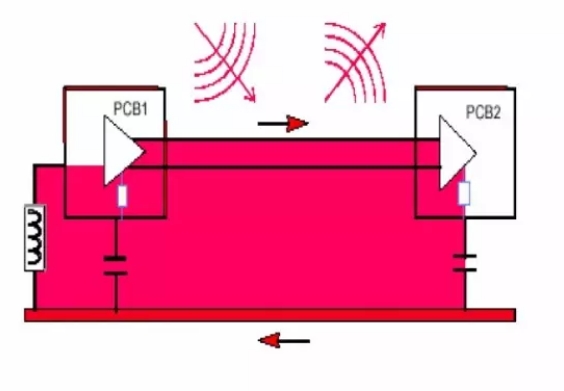

In the high-voltage direct current power distribution system of data centers, the performance of high-voltage resistors directly affects the efficiency of power conversion. The high-voltage resistor with glass glaze coating can withstand A 5kV DC voltage and has a leakage current of less than 1μ A. Combined with the dynamic resistance regulation achieved by intelligent algorithms, the system energy efficiency is improved by 3.2%.

This technological revolution in resistors is essentially a deep integration of materials science and precision manufacturing at the microscopic scale. From nanoscale precision to three-dimensional structural design, the iterations of these fundamental components are reshaping the performance boundaries of modern circuits, and their influence will gradually permeate every corner from consumer electronics to industrial control.